A brief introduction of ammonia desulphurization

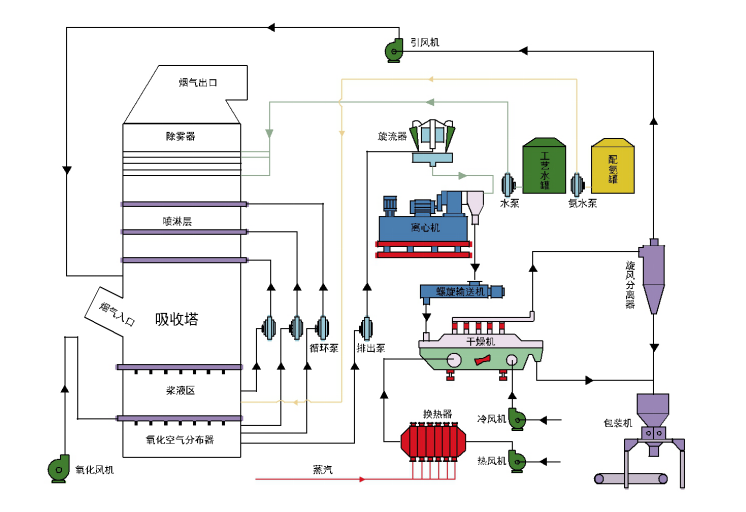

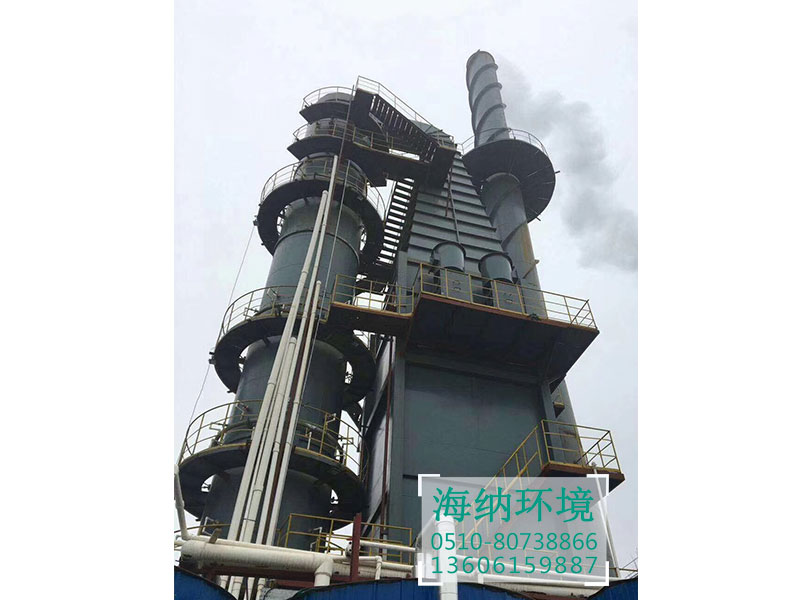

Ammonia desulphurization is the control of SO2 emission. It not only eliminates a large amount of SO2 in flue gas, but also produces high value-added sulphuric acid ammonia fertilizer products. The system uses a certain concentration of ammonia (28% as an example) as the desulfurizer, and produces the sulphuric acid ammonia slurry, which is transported to the chemical fertilizer plant treatment system. Ammonia water demand for ammonia desulphurization is automatically adjusted by the preset PH control valve and measured by the flowmeter. The sulphuric acid ammonia crystals crystallized in the desulfurization tower saturated ammonium sulphate slurry and generated 3 to 5% weight ratio of suspended particles. These serous quilts are pumped to the processing field, dehydrated through primary and two stages, and then sent to the chemical fertilizer plant for further dehydration, drying, condensation and storage, thus producing considerable by-products at the same time of flue gas desulfurization, and the desulfurization and dust remover achieves certain economic benefits.

A brief introduction of ammonia desulphurization

Ammonia desulphurization is the control of SO2 emission. It not only eliminates a large amount of SO2 in flue gas, but also produces high value-added sulphuric acid ammonia fertilizer products. The system uses a certain concentration of ammonia (28% as an example) as the desulfurizer, and produces the sulphuric acid ammonia slurry, which is transported to the chemical fertilizer plant treatment system. Ammonia water demand for ammonia desulphurization is automatically adjusted by the preset PH control valve and measured by the flowmeter. The sulphuric acid ammonia crystals crystallized in the desulfurization tower saturated ammonium sulphate slurry and generated 3 to 5% weight ratio of suspended particles. These serous quilts are pumped to the processing field, dehydrated through primary and two stages, and then sent to the chemical fertilizer plant for further dehydration, drying, condensation and storage, thus producing considerable by-products at the same time of flue gas desulfurization, and the desulfurization and dust remover achieves certain economic benefits.